Page 7 of 9

Re: Next Project

Posted: Sat Nov 14, 2015 8:53 pm

by mdmax72

Had a read up about Anodising. Bit more to it than l thought.

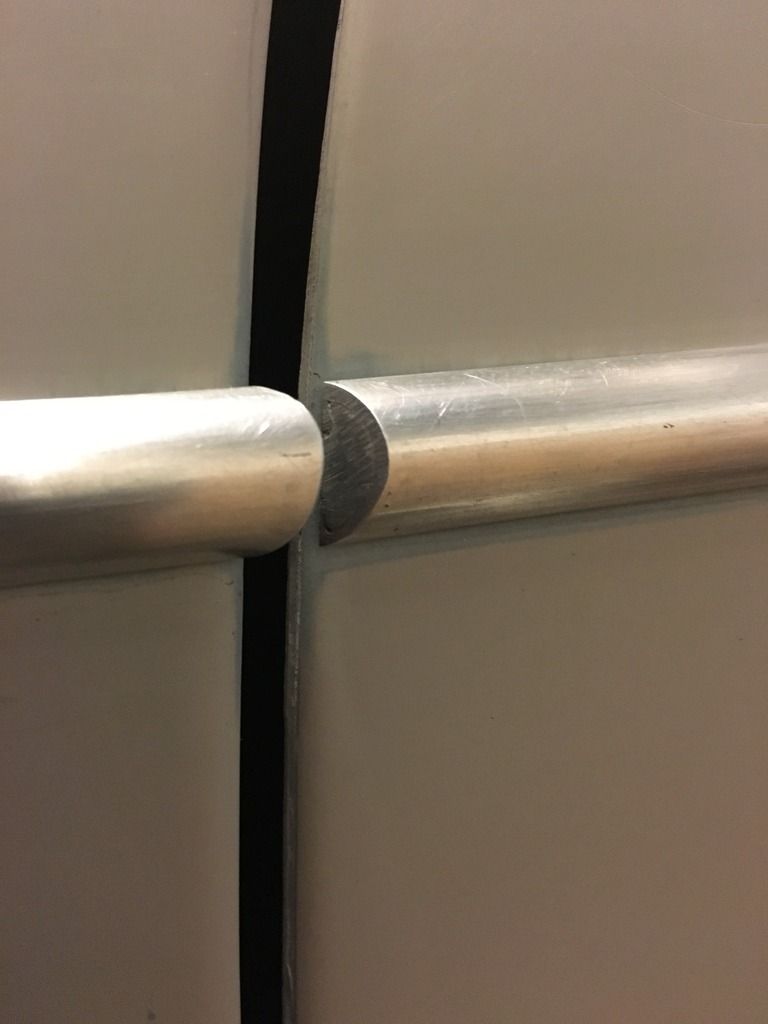

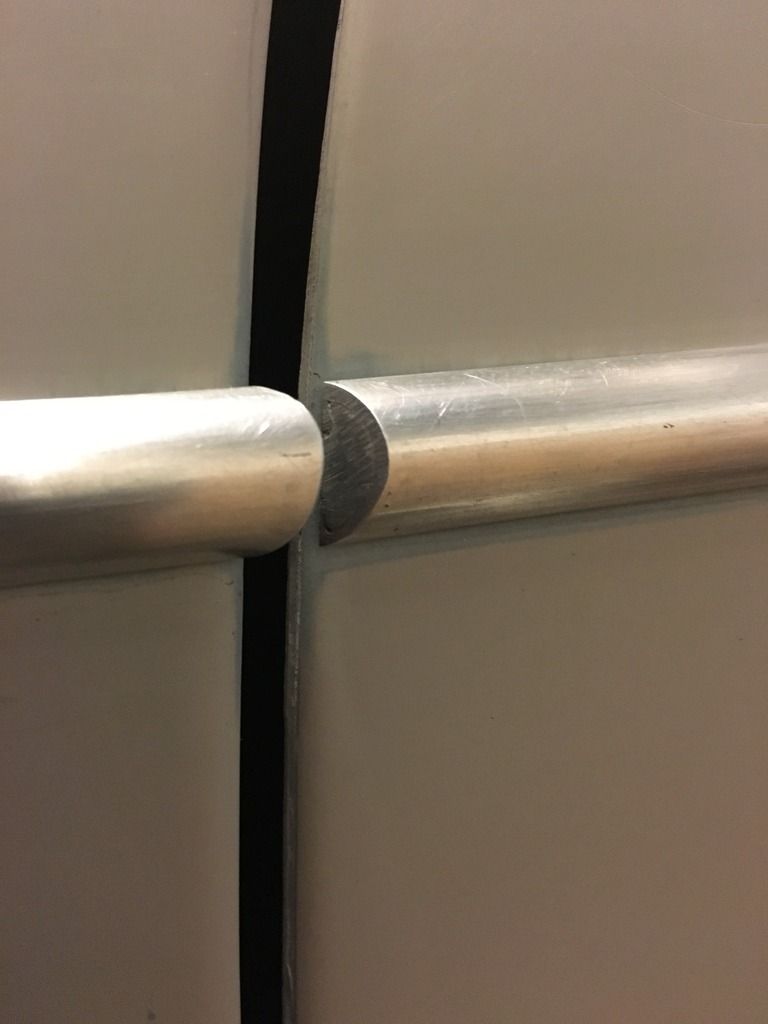

The screen surround isn't anodised and I've sanded and buffed that up a few times so spent the day polishing/buffing up the posts to see how they turn out. Never again. Here they are fitted and with seals in place.

Re: Next Project

Posted: Sun Nov 15, 2015 7:43 am

by greg356a

Hi Rich, they look brilliant.

Maybe instead of a hard anodise coating just a clear powder coat would work?

I am not sure how successful clear coats are to weather environments. Years ago I was involved in salt spray tests on aluminium product and at that time anodise would give a good ten years whilst clear powder coat was more like 5 years. Today of course a dyed powder coat (Chrome) can easily achieve 10 years plus. Down side of anodise is finding someone to do a "show quality" finish and if it does get damaged not easy to touch up. Of course the 911 RS Fuchs used silver anodise to great effect.

Struggling on my seats as to what finish to use. I live relatively close to a show quality powder coater (Aerocoat) who specialise in motor bikes, wheels etc. As my seats have a hand beaten appearance the powder coat would hide some of the blemishes which Hard coat anodise would not.

Anway they look great as they are

Re: Next Project

Posted: Mon Jul 09, 2018 2:45 pm

by greg356a

Hi Rich,

Despite having tons of stuff on the To-Do list I was tThinking about my next single project as fitting electric windows to work with the screen/ hardtop.

Do you have a list of parts/dims/ suppliers you used? I was thinking particularly of the aluminium sections, fuzzy window strips, rubber sections, glass etc. I like the ali section used for guiding the glass up and down but getting the right size combination to allow for fuzzy gasket and glass parts must have been a nightmare!

Not sure whether to use some window power regulators from a VW golf/ passat or to use some off the shelf options. VW would be better quality but newer versions would be digital so would not work with my loom.

Any guidance really appreciated

Re: Next Project

Posted: Thu Jul 12, 2018 9:55 pm

by mdmax72

Hi Greg

Sorry only just noticed you had posted.

It seems all the pics are back in the thread from Photobucket. Not sure if l kept a list of what l used or suppliers. I’ll have a look and see.

It won’t be an easy task with regards to sealing to screen frame and hard-top but l do think it’s doable. I do have the original Chesil steel frames you could borrow. Which might be a reference point to go from?

With regards to regulators, do the Vw Golf or Passat use cables and pulley system to lift and lower the window??

Re: Next Project

Posted: Wed Jul 18, 2018 8:50 am

by mdmax72

Hi Greg

Ive had a look and didn’t keep a record of what l used and from were. Happy to pull a door card off and have a measure of what l used if required.

Are you managing to put a few shakedown miles on the car with the weather so good.

Re: Next Project

Posted: Wed Jul 18, 2018 1:05 pm

by greg356a

Hi Rich,

Unfortunately/ fortunately work has been good so I have not managed anymore miles.

Any chance of some outer/ inner dimension/ pictures of your original steel runners? did you make the ali the same?

The three parts that need to work together for me seem to be the glass sliding in the furry gasket which is held inside the u section of the aluminium runner. So it must be 4mm or 6mm glass, 1mm gap around gasket to allow glass to slide and then glue gasket into the something like a 10 to 12mm channel. Any help appreciated.

Can your glass people cut flat glass and round/ polish the edges?

Re: Next Project

Posted: Sat Jul 21, 2018 11:37 am

by mdmax72

Hi Greg

Yes l basically made the aluminium frame the same as the steel ones apart from extra braces in the corners. Just looked back in this thread and there’s some pics on page 3 of the steel and aluminium frames. All the mounting tabs are also in the same locations.

The size of the U channel is 15x15x15x1.5 wall. The felt glass Chanel is 12mm wide so sits snug inside the U channel. The felt channel will except 4-6mm glass. I got the Fury glass channel from Wollies Trim. I’m using 4mm glass and works fine. Think 6mm glass would be abit on the tight side and put a strain on your electric motors. Are you going to make the pillars removable?

I’m sure Robneal had some side glass made for his Coupe build. Not sure what company he used but do recall him mentioning he would recommend them. Might be worth giving Rob a shout if he doesn’t chirp in.

Re: Next Project

Posted: Sat Jul 21, 2018 1:11 pm

by greg356a

Hi Rich,

Thanks, I found an aluminium channel 14x15 with fury pile which clips in, from Paul Beck Vintage Supplies. Like yours is accepts 4 to 6 mm glass. I need to find a power regulator whether its universal or second hand not sure. Gary sells a nice power window kit. I have even wondered about old school beetle hand wind up windows. Yes hoping to have the post removable or maybe some part of the hardtop, just at the ideas stage. Also looking at the sealing of the glass to the doors maybe a simple gasket and how does the water get out, hole in the bottom?

I am hoping to be able to get the hardtop to fit, power windows fitted so that it is weather tight ready for the winter.

But there are several issues to over come, how to weather seal the hardtop at the windscreen, hold the hard top down at the back and seals, whether it needs any internal frame (metal/ grp) for fixings etc. I wondered if I could use the centre windscreen pillar (beefed up) to also act as part of the clamp for the hardtop to reduce the stress on the windscreen. I might seen if I can get a boxster top and cannibalise that for parts. Already looked at the size it don,t fit. Too many questions at this stage, but need to start somewhere.

Re: Next Project

Posted: Sat Jul 21, 2018 7:56 pm

by mdmax72

Think i’d be leaning towards just using the Beetle regulator. Keep it simple, that way it’ll never let you down. In fact Chesil use the Beetle regulator with a tweak to accept a different hand crank. Why l don’t know.

Can you not use the same method of attaching the soft top, to the windscreen frame. But swap it for the hard top?

Re: Next Project

Posted: Sun Oct 14, 2018 1:04 pm

by mdmax72

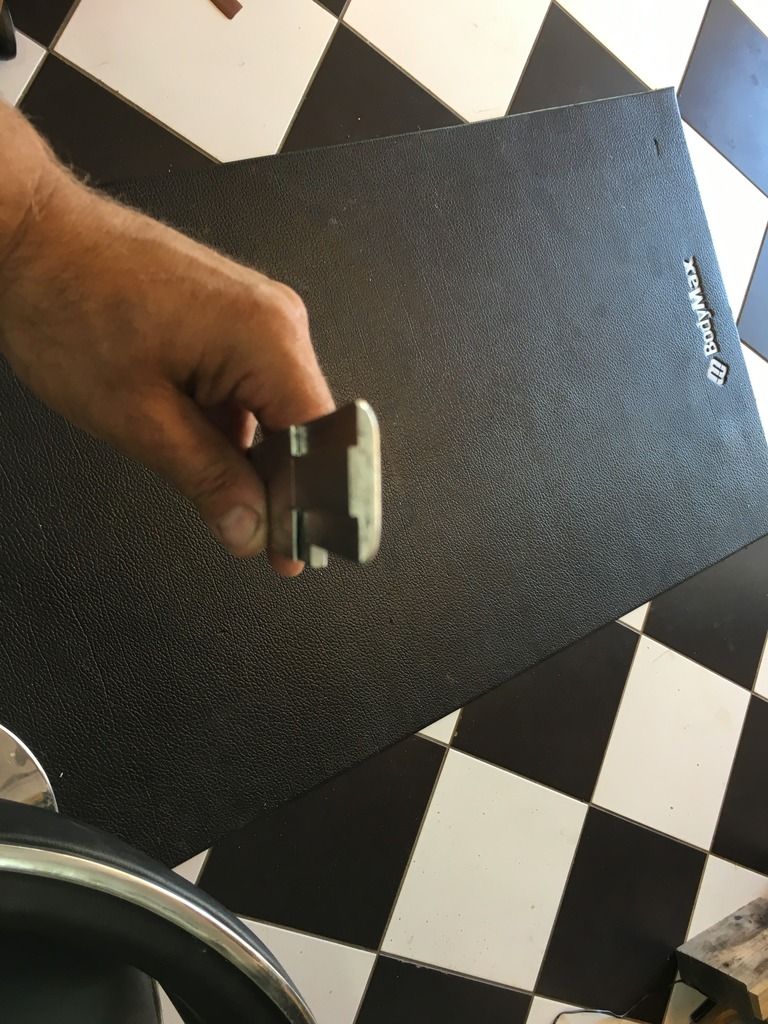

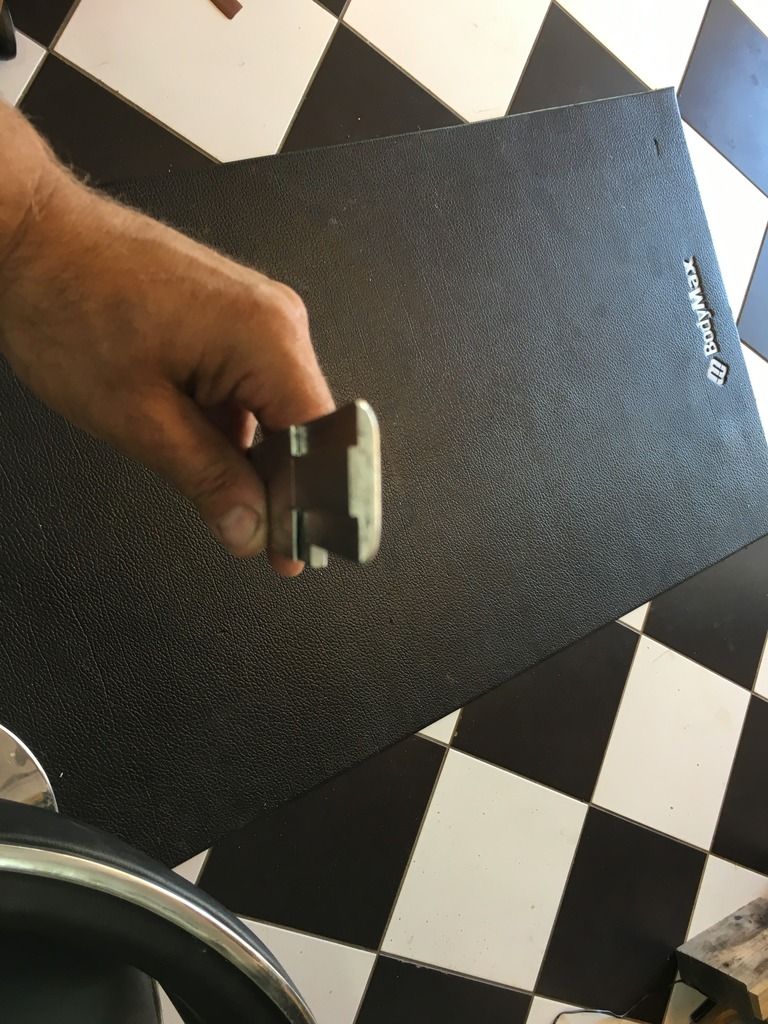

The GT bumper trim ends need finishing. This is what l have.

Whilst I’ve got a few jobs to do on the car l thought l might aswell tackle them. Now l didn’t want to wrapped them round the bumper ends. Still seemed unfinished to me. Other alternative was to tig the ends and shape, until l looked closer at the side trim spears ends on the car. These have an insert fitted to them to close the end.

With alittle bit of manipulation i’ve shaped a flat bar the same profile as the bumper to act as an insert.

And this is how it fits with a scrap piece of trim.

So the idea is to cut of a 3/4” piece and fit into each of the bumper ends and shape accordingly.

Re: Next Project

Posted: Sun Oct 14, 2018 5:51 pm

by greg356a

I think you are right not to wrap around the bumper it would look unfinished. They should look great with the infill.

Re: Next Project

Posted: Mon Oct 22, 2018 10:17 pm

by mdmax72

Re: Next Project

Posted: Tue Oct 23, 2018 5:02 pm

by greg356a

Extra awesome result!

Re: Next Project

Posted: Fri Jan 18, 2019 1:39 pm

by mdmax72

Not posted for a while. So a quick update.

Pulled the plug and bought a new set of wheels.

And this is how the look now after having the done in black.

Gearbox is the next on the list, as it’s not coping with the extra grunt.

Re: Next Project

Posted: Fri Jan 18, 2019 5:01 pm

by hot66

Very nice Rich

Much weight saving ?