After spending a good part of last summer refurbishing the boat I was able to get it in the water at the very end of the season. It was the last decent day we had, even though it was only 50°.

After launching the boat I realized how nasty the trailer looked. Obviously, it had seen a lot of miles on the road as all of the forward facing surfaces were pocked with rust spots where stones had chipped the enamel paint. Since the boat has been invited to shows this year I thought that the trailer needed to go, or be refurbished. I researched what boat trailers looked like in the '50s and found that they haven't changed much at all. That made me take a look at restoring, rather than replacing the trailer.

I took lots of pictures of the supports and how they were placed. I found many bent parts that led me to believe that the supports were not in their original position.

I hate rust.

A couple of hours with a couple of good friends and the trailer was stripped to its bare bones. Every part that could be removed, was.

I dropped three come-alongs from eye-hooks in the girders above, giving me the ability to position the chassis where I want it.

The right rear step had been banged up so I decided to lift it up to work on it.

The metal needed to be pounded outward before it could be reshaped so I heated it from the bottom side and used a blunt chisel to reshape it from the inside. There is definitely something about heating metal to cherry red and massaging it into a new form with heat that appeals to my baser instincts.

Grinding down the tool marks is very satisfying, too.

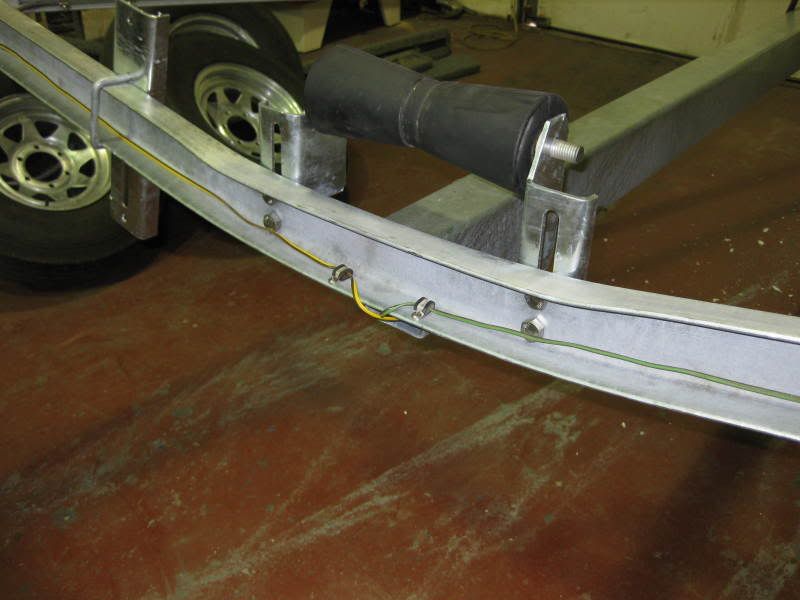

I noted that everything that was painted or zinc plated, rusted, and nothing that was galvanized was even blemished. That's when I investigated the galvanizing process. We have a local facility that's part of a national chain. I paid a visit to their facility and got a tour of their plant. I was pretty impressed. I talked to the manager and found that galvanizing is very reasonable. I thought their pricing structure was very interesting, too. Sand-blasted metal parts are $.35 a pound to galvanize. It saves two steps over bringing them metal that's ever been painted.

There are a lot of parts to a trailer.

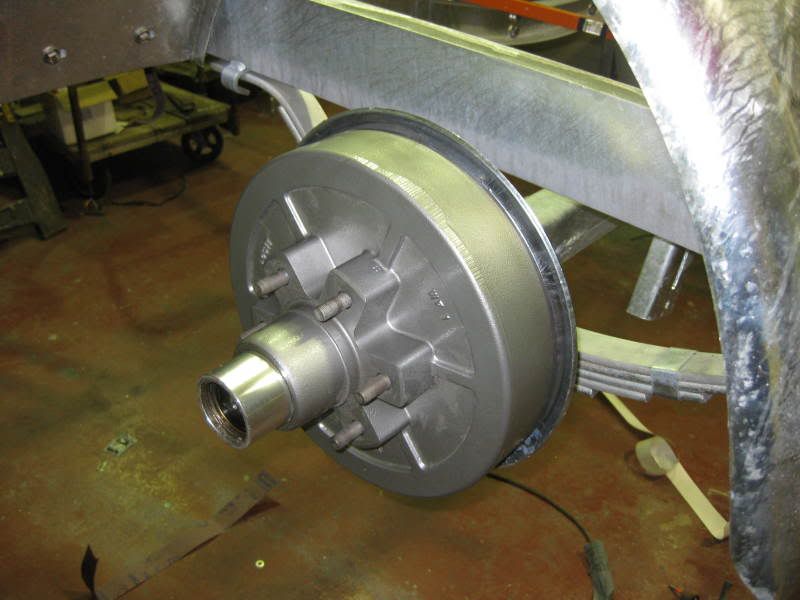

I could have sand-blasted the frame and wheels but they only charged $.21 a pound to burn off the paint. A 20 lb. wheel cost $4.00 to clean. Not worth my time or my sand. The same for the frame. They simply dipped it in the molton zinc tank which is kept at 850°F. That removes 99 44/100% of the paint, but not all of it. Hand detail work is required to get a good job.

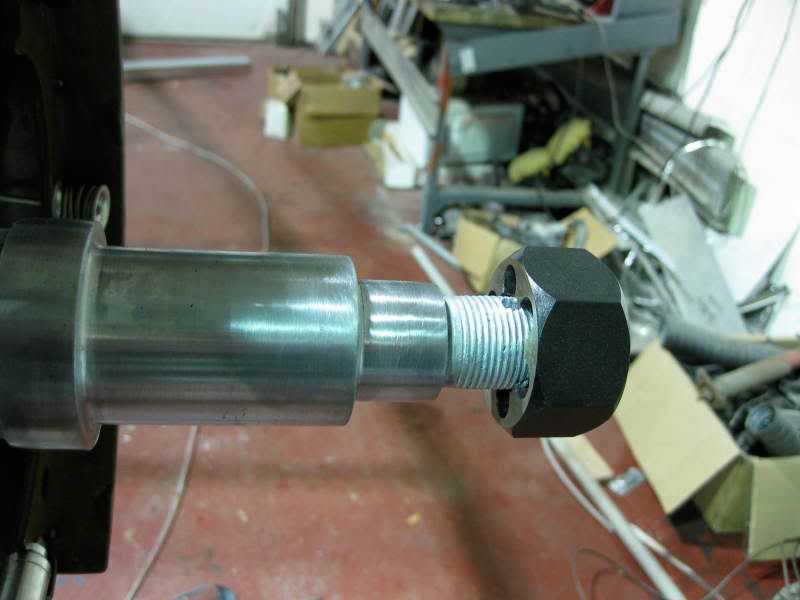

After it's cleaned it's dipped into several acid and neutralizer tanks to remove any trace of zinc from the dip. Then it goes back into the molton zinc where it chemically bonds to the steel. Great care was used to drill holes into areas that would have trapped air, keeping the metal from reaching the surface of the cleaned steel. I had a decision to make as to whether to quench the hot parts or let them cool naturally. The concensus of people I asked said that quenching might make the trailer chassis too brittle for the use.

Here's the pile of parts awaiting the galvanizing of all the nuts and bolts. I'll send a truck to pick it up tomorrow. The pallet on the right has the three trailer wheels wrapped up. You can see the axle underneath the trailer and the pallet under the trailer contains all the other metal parts.