Page 7 of 8

Re: 914 engine core, strip and rebuild

Posted: Sun May 14, 2017 11:44 am

by greg356a

It will be really interesting to see the bhp/ torque values. Possibly more than my 2.7, given my engine transmission is considerably heavier I wonder how different the will drive. Assuming I ever get mine finished and tested. Look forward to seeing the car in sunny Norfolk

Re: 914 engine core, strip and rebuild

Posted: Fri Jun 16, 2017 11:08 am

by mdmax72

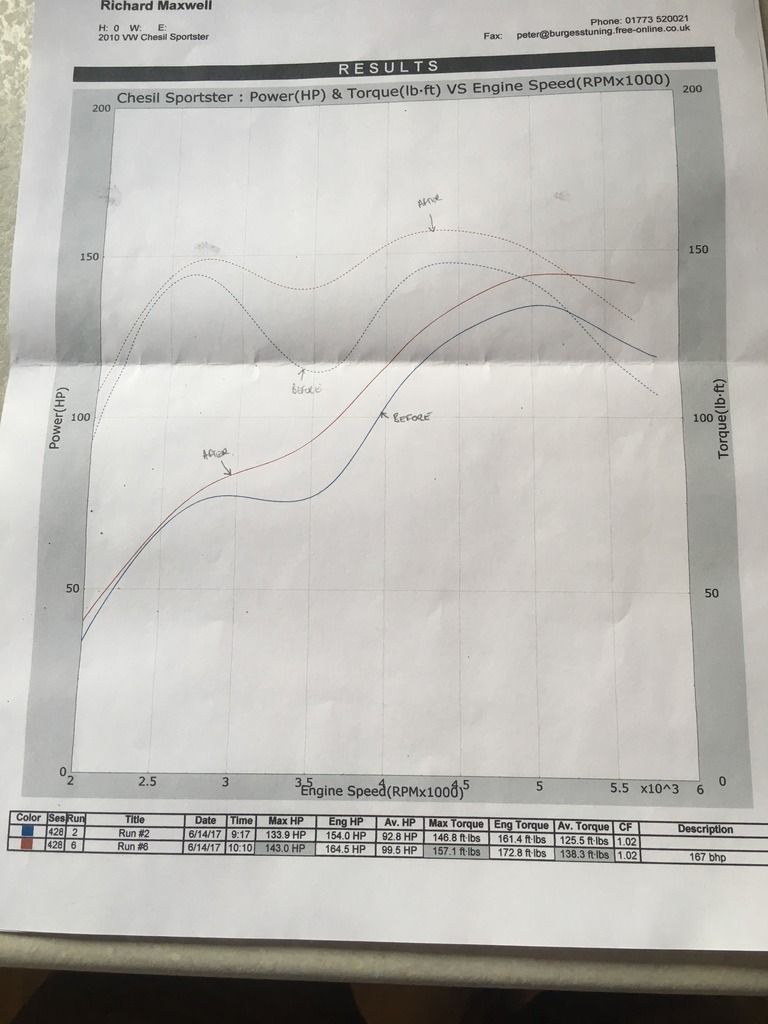

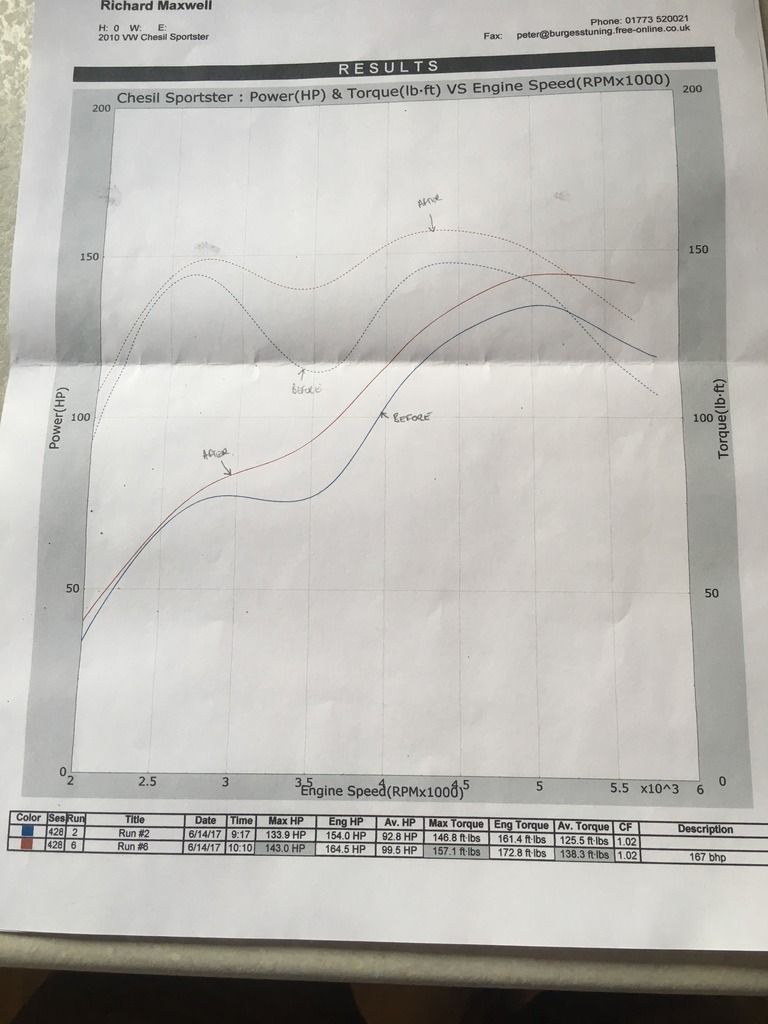

So dyno day has arrived.

And the most important bit.

And a short video. Seems I've got a air leak in the exhaust.

https://youtu.be/ABQBBfa9sA8

Re: 914 engine core, strip and rebuild

Posted: Fri Jun 16, 2017 8:50 pm

by Robneal

Impressive output.....is it good to drive too? right through the Rev range? Sounds great as well...How many miles under its belt now and any plans for any further changes???

Sent from my SM-G930F using Tapatalk

Re: 914 engine core, strip and rebuild

Posted: Sat Jun 17, 2017 8:19 am

by greg356a

Bhp/ton must be quite impressive?

Look forward to seeing it in the flesh, baggsy shotgun

Re: 914 engine core, strip and rebuild

Posted: Sat Jun 17, 2017 9:51 am

by mdmax72

Cheers guys.

Just done the calc for bhp/ton and it comes at 196. If that's correct?

Next job is to install Oil thermostat and oil coolers. Should of done this from the beginning but wanted to see how it held out without. Just so I know it's money well spent and a comparison. It's been within temp whilst the weather has been cooler but now it getting warmer it's getting boarder line.

Think I'm gonna run the Oil lines up front and put a Oil cooler behind each of the horn grills. Similar to what was done by Porsche in the day. Did you use one oil cooler in yours Greg?? If so what size??

Found the air leak in the exhaust also. So that should stop it sounding like a fire cracker...

Re: 914 engine core, strip and rebuild

Posted: Sat Jun 17, 2017 12:16 pm

by greg356a

That figure sound about right and puts you at the same as Porsche boxster 3.2 - awesome.

Yes I used huge custom made oil lines from back to front via a 944 thermostat and an original 911 oil cooler right at the front underneath in the air flow fingers crossed.

Re: 914 engine core, strip and rebuild

Posted: Sat Jun 17, 2017 12:41 pm

by Bruce M

Maybe start with sealing up the engine tin completely?

VW & Porsche made sure there was an airtight seal between the lower side of the engine & the top. The tight fitting tin, those little spark plug wire seals, the rubber or foam seal between body & tinwear, various other rubber seals, etc, were all there for a good reason and make the cooling air as effective as possible. Your pulley tin is a airpath for roasting hot air to rise up from around the exhaust as the hot air is drawn up (how a chimney works). I'd suggest adding a section underneath to wrap around the pulley like the stock T1 tin does and careful close any other holes or gaps around the tin wear.

Re: 914 engine core, strip and rebuild

Posted: Tue Jun 20, 2017 2:52 pm

by mdmax72

Cheers for the tips Bruce. I've already got the engine compartment all sealed including the spark plug holes.

What sort of size Oil Cooler did you use Greg. One in each wheel arch??

Re: 914 engine core, strip and rebuild

Posted: Tue Jun 20, 2017 3:21 pm

by greg356a

Hi Rich,

Just one oil cooler mounted centrally and now angled slightly down to allow air to pass over. There is also pics of thermostat and dry sump oil tank which is under the rear wheel arch. In my Coupe I run a type 1 1776cc with large hoses back to front of car and a oil cooler. I don't have a thermostat so cold in winter and ok in most summer days. I wonder if you could get some sort of adjustable thermostat to regulate temp, maybe use a cooling fan with a control?

POsition different to that shown

Old picture but shows location without body fitted

Re: 914 engine core, strip and rebuild

Posted: Tue Jun 20, 2017 6:07 pm

by Bruce M

mdmax72 wrote:Cheers for the tips Bruce. I've already got the engine compartment all sealed including the spark plug holes.

Ah, so you've already added more tin sections to shield this area?

Not a major hot side leak but common gap in DTM tin and slight efficiency loss.

Re: 914 engine core, strip and rebuild

Posted: Tue Jun 20, 2017 10:02 pm

by Robneal

So the under pulley tin, have people.made this from scratch or have modified type.1.tin. any pictures greatly appreciated

Rob

Sent from my SM-G930F using Tapatalk

Re: 914 engine core, strip and rebuild

Posted: Wed Jun 21, 2017 11:37 am

by Spyder-finder

That small gap is not a big problem when you are driving along, only if you get stuck in traffic on a hot day.

You are better off adding some exhaust wrap or ceramic coating to keep the exhaust temps down.

Re: 914 engine core, strip and rebuild

Posted: Thu Jun 22, 2017 1:41 pm

by mdmax72

Bruce l see your concern. A gap is a gap. The pulley tin wasn't altered from using the pulley that came with the DTM. It was larger hence the gap around the pulley you see in the pic your posted. I'll watch this area with interest and see.

As l had to take the manifold of to weld the mounting tabs. I've already sent it to be Ceramic coated and should be being applied as we speak. So let's see how good it is when it comes back.

Re: 914 engine core, strip and rebuild

Posted: Sat Jun 24, 2017 6:48 pm

by Robneal

Not sure I'm going to get much heat up the Pulley hole on mine as I am using the Vintage Speed Exhaust and manifolds which will mean the heat will be more focused at the sides of the engine and not underneath. As seen in the photo below....

One other question was on the oil thermostat. The 944 thermostat has an operating temperature of much lower than of a typical air cooled engine are you using a different spring, or just opening the thermostat at a lower temperature?

Re: 914 engine core, strip and rebuild

Posted: Tue Jun 27, 2017 10:06 pm

by mdmax72

A little progress routing the pipe work around the chassis. What a pain in the ass this is.

I'm upto the front wheel arch, just need to get the oil cooler frames I've made welded and then l can finish the front.